Best Features

Uniform Thickness- Each panel of Bigwig Film Face Plywood is manufacture in such a way that it has uniform thickness which help to get smooth surface during the shuttering work.

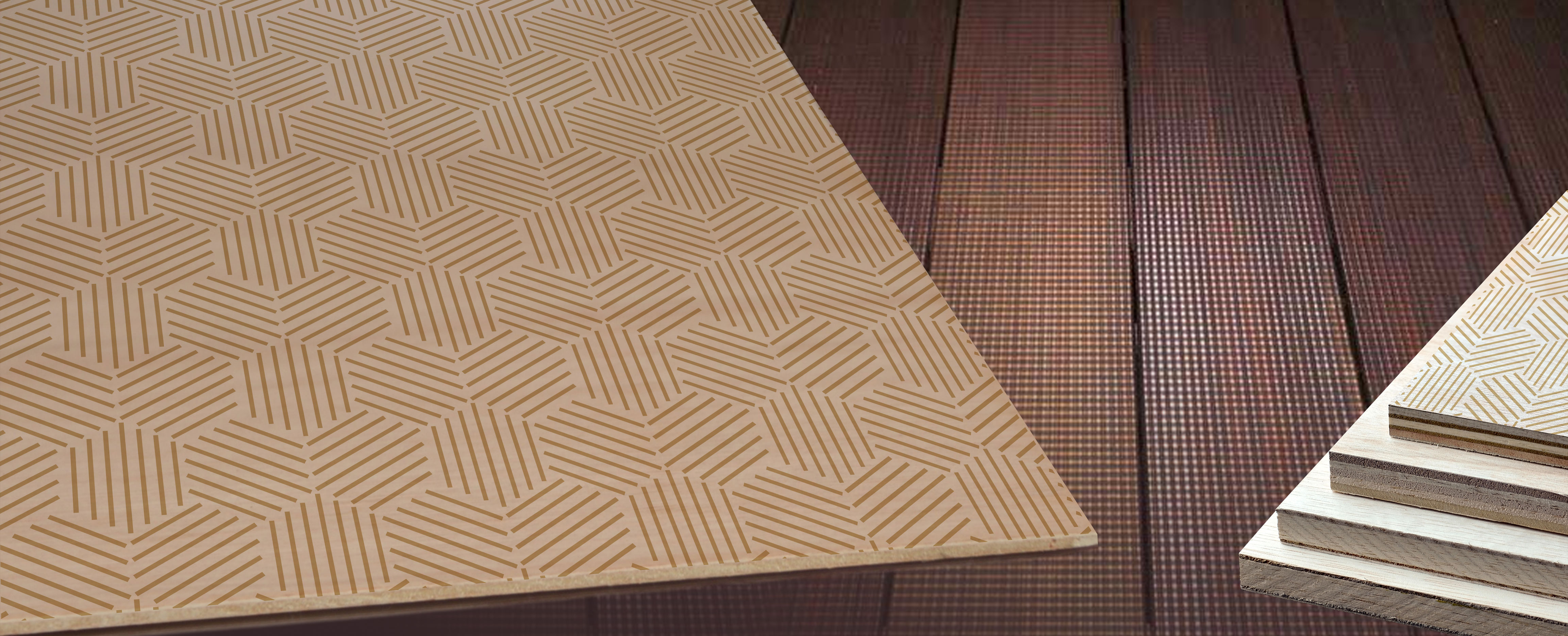

Mirror like finish to provide smooth surface- Pressed in high pressure hydraulic press & high gsm PF resin coated film provides Bigwig film face plywood mirror like finish.

100% Core gap free- Assembled by trained assemblers in the supervision of quality control person with wider core to minimize the chance of any core gap inside the panels.

Every Layer in Resin Coated- In Bigwig Film face shuttering ply, all the layers are glue lined from both sides. This practice prevents the ply from swelling when heavy load of concrete is poured over it. Thus ensures more repetitions!

Certain measures if followed can enhance the life of Bigwig Film Face Plywood—

- Do not drag or drop from height.

- Stack on flat surface.

- Clean both side surfaces after use.

- Apply mould oil after 3-4 uses.

- Use sealant on cut edges.

- Use minimum nails.

- Use putty in the nail holes.

Bigwig Fim face Plywood

advantages over ordinary film faced ply:

- It gives more number of repetitions.

- Provides smooth surface to concrete form work.

- It is economical in ratio to its number of uses.

- After using it as shuttering plywood for many times, its salvage can be used for paneling, roofing, flooring, partitions and manufacturing of furniture.